Leave Your Message

Phthalic Anhydride is a vital chemical used in various industries. Its versatility makes it essential for applications ranging from plastics to dyes. Understanding how to use Phthalic Anhydride effectively can enhance product performance.

In the production of plasticizers, Phthalic Anhydride is crucial. It improves flexibility and durability. However, improper usage can lead to suboptimal results. For instance, using too much can alter the plastic's properties adversely.

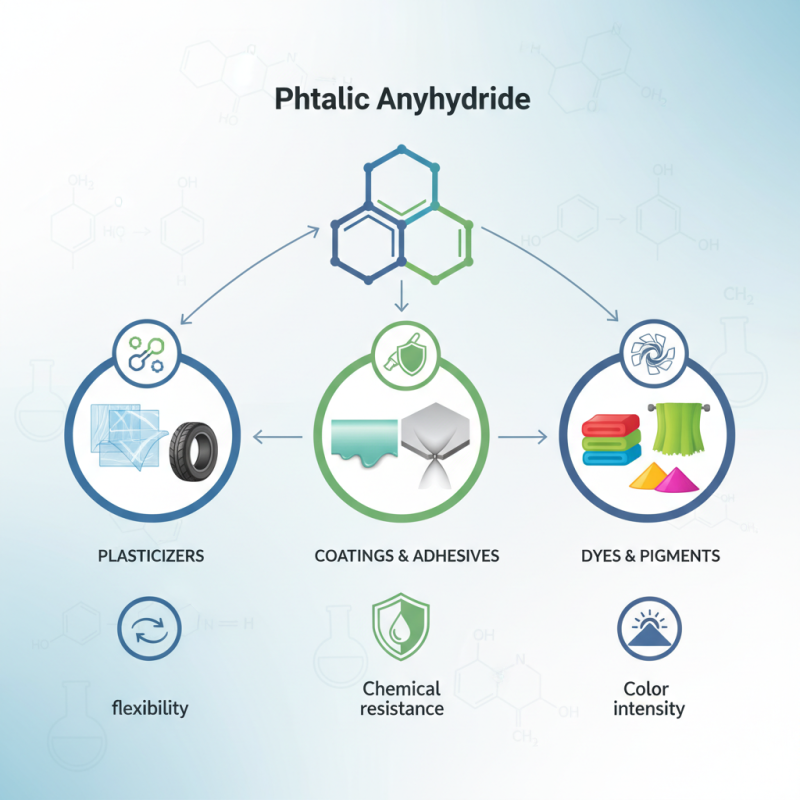

In addition to plastics, Phthalic Anhydride is used in coatings and adhesives. It promotes adhesion and resistance to chemicals. Yet, it requires careful handling during mixing. Mistakes can lead to ineffective formulations. Each application area teaches us the importance of precision and understanding, which can't be overlooked.

Phthalic anhydride is a crucial chemical compound widely used in industry. Its diverse applications stem from its unique chemical structure. It has a molecular formula of C8H4O3, indicating two carbonyl groups that make it reactive. This property is vital for producing plastics, resins, and dyes. In 2021, the global phthalic anhydride market was valued at approximately $4.4 billion, showcasing its significance.

In products like alkyd resins, phthalic anhydride enhances durability and weather resistance. It also plays a role in plasticizers, which increase flexibility in materials. Understanding its chemical reactions is essential for maximizing its benefits. Data suggests that demand in adhesives and sealants is on the rise, with a projected growth rate of 4% annually.

Tips for using phthalic anhydride effectively include maintaining precise temperature control during synthesis. Excess heat can cause unwanted by-products. Always wear protective gear as it may cause irritation upon contact with skin. Finally, consider the risks of handling phthalic anhydride. While it has numerous benefits, proper safety protocols must guide its use. This attention to detail can prevent costly mistakes.

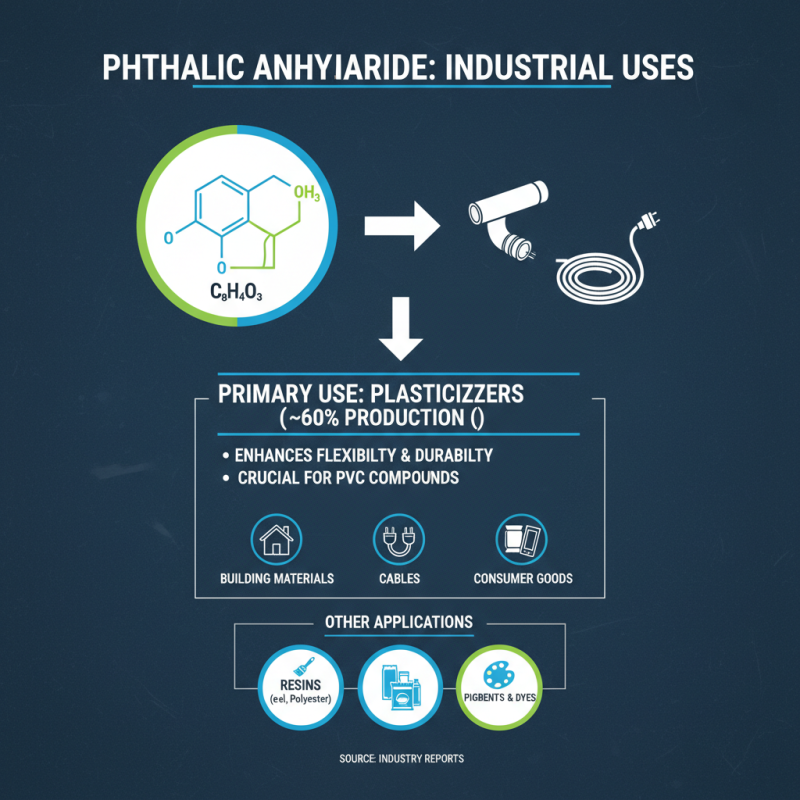

Phthalic anhydride plays a crucial role in various industrial applications. In the production of plasticizers, it significantly enhances flexibility and durability. Industry reports suggest that approximately 60% of phthalic anhydride produced is used for this purpose. These plasticizers are extensively utilized in polyvinyl chloride (PVC) compounds, making them vital for building materials, cables, and consumer goods.

Another prominent application lies in the synthesis of resins and coatings. Phthalic anhydride is a key ingredient in alkyd resins, known for their excellent adhesion and durability. The demand for high-quality coatings is rising, driven by the construction and automotive sectors. However, formulators must note that improper use can lead to lower performance. Incomplete reactions or poor processing conditions can result in lower-quality products.

Yet, phthalic anhydride's role in the production of dyes and pigments is often overlooked. These compounds enhance color fastness and stability. Industry statistics reveal a significant growth rate in dyes, suggesting potential for expansion. Companies must ensure they meet quality standards to remain competitive. Balancing performance with environmental regulations remains a challenge—one that requires constant reflection and adjustment in manufacturing practices.

Phthalic anhydride is widely used in various industrial applications. Effective processing techniques can significantly enhance its utility. One key technique is continuous production. It ensures consistent quality, reducing waste. According to industry reports, continuous processes can increase yield by 15% compared to batch processing. This is crucial in maintaining competitive pricing.

Another effective technique is the optimization of reaction conditions. Adjusting parameters like temperature and pressure can lead to higher efficiency. Studies have shown that operating at optimal conditions can improve reaction rates by up to 25%. Still, it’s essential to monitor each step closely. Overlooking temperature fluctuations may lead to unwanted byproducts.

The choice of catalysts also plays a crucial role. Selecting the right catalyst can enhance reaction speed and selectivity. However, not all catalysts perform well with phthalic anhydride. Testing various options is necessary, even if it involves time and resource investment. Some may find this process frustrating, but the benefits often justify these efforts. Balancing effectiveness with cost remains a challenge.

Phthalic anhydride is widely used in different applications, including plasticizers and resins. However, safety is paramount when handling this chemical. Exposure to phthalic anhydride can cause respiratory issues and skin irritations. According to the National Institute for Occupational Safety and Health, the permissible exposure limit is set at 1 mg/m³ over an eight-hour workday. Ensuring compliance with these standards is crucial.

Proper personal protective equipment (PPE) is essential. Workers should wear gloves, goggles, and respirators to minimize risk. A well-ventilated workspace is equally important. Ventilation helps disperse any airborne contaminants. Reports indicate that inadequate ventilation can lead to an increased incidence of respiratory problems among workers.

Emergency procedures should be clearly outlined. This includes knowing how to handle spills and exposure incidents. Training staff in these protocols can significantly reduce safety risks. It is alarming to note that many facilities lack comprehensive training programs for phthalic anhydride handling. Regular audits and safety drills can make a significant difference. They create an environment of preparedness and awareness, greatly enhancing safety in handling phthalic anhydride.

| Application | Key Benefits | Safety Measures | Handling Practices |

|---|---|---|---|

| Production of Plasticizers | Improved flexibility and durability | Use gloves and goggles, ensure good ventilation | Store in cool, dry place; avoid contact with skin |

| Manufacturing of Resins | Enhanced thermal stability | Wear appropriate protective equipment | Handle in a fume hood; do not breathe vapors |

| Synthesis of Dyes and Pigments | Vibrant colors and high stability | Avoid inhalation and skin contact | Use in a well-ventilated area; dispose of waste properly |

| Manufacturing of Adhesives | Strong bonding properties | Follow MSDS instructions for safe use | Keep away from heat sources; ensure lids are tightly closed |

| Insecticides and Herbicides | Effective pest control | Use protective gear; avoid contamination | Store away from food and feed; follow application guidelines |

Phthalic anhydride has numerous applications that are evolving rapidly. In the construction industry, its use in producing durable coatings is expanding. These coatings are vital for weather resistance and maintaining structural integrity. New formulations are being developed to enhance these properties. However, the environmental impact of these innovations remains a concern, requiring careful consideration.

In the field of plastics, phthalic anhydride plays a critical role too. It acts as a plasticizer, improving flexibility and strength. Companies are now exploring bio-based alternatives to reduce reliance on petroleum products. This shift could offer sustainability benefits but may also impact cost and availability. Not all innovations yield the desired results. Some require extensive testing before they can be adopted.

Additionally, the pharmaceutical sector is seeing new uses for phthalic anhydride in drug formulation. This could improve drug stability and efficacy. Yet, there are challenges in ensuring safety and compliance with regulations. The path forward will involve balancing innovation with responsible practices. The future of phthalic anhydride applications is filled with potential, but vigilance is necessary to address any issues.