Leave Your Message

In the realm of advanced materials, Tetrabromo Phthalic Anhydride (TBPA) has emerged as a pivotal compound in various applications, notably in the fields of flame retardancy and polymer chemistry. According to a market analysis by Grand View Research, the global flame retardant market size was valued at approximately $8.1 billion in 2020, with projections suggesting a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028. As industries strive to adhere to stringent safety regulations, the demand for effective flame retardants like TBPA is surging, highlighting its importance in manufacturing practices.

Moreover, the versatile nature of Tetrabromo Phthalic Anhydride allows it to be incorporated into a wide array of products, including resins, coatings, and textiles. A report by Markets and Markets indicates that the global market for halogenated flame retardants is expected to reach $5.3 billion by 2023, driven by the increasing need for enhanced fire safety standards in construction and automotive sectors. Thus, understanding how to effectively utilize TBPA in your projects is not just beneficial—it's becoming essential. This guide aims to provide insights into maximizing the potential of Tetrabromo Phthalic Anhydride, ensuring that both product efficacy and safety are at the forefront of your development processes.

Tetrabromo phthalic anhydride (TBPA) is a halogenated compound that is primarily utilized in the production of flame-retardant materials. Its molecular structure features four bromine atoms, which significantly enhance its fire-resistant properties. This compound exhibits a high thermal stability and low volatility, making it an ideal choice for applications in various industries, including plastics, resins, and coatings. The incorporation of TBPA into formulations helps to reduce flammability and restrict the spread of fire, thus increasing the safety of the final products.

In addition to its flame-retardant properties, tetrabromo phthalic anhydride is known for improving the mechanical strength and durability of materials. It is commonly used in the manufacturing of epoxy resins, which are widely employed in electronics, automotive parts, and construction materials. TBPA can also function as a reactive intermediate in the synthesis of specialty chemicals. Its versatility and effectiveness make it an essential ingredient for enhancing the performance and safety of various applications, making it a valuable asset in many industrial projects.

Tetrabromo Phthalic Anhydride (TBPA) has gained recognition across various industries due to its unique properties and advantages. One of the most significant benefits of TBPA is its exceptional flame retardancy, making it an ideal additive in plastics, textiles, and electrical materials. This characteristic not only enhances safety by reducing the risk of fire but also helps manufacturers comply with stringent regulatory standards aimed at protecting consumers and the environment.

In addition to its flame-retardant qualities, TBPA also contributes to improved thermal stability and mechanical strength in composite materials. These enhancements are particularly valuable in the automotive and aerospace industries, where performance and safety are paramount. Furthermore, TBPA's versatility allows it to be used in coatings and adhesives, where it adds durability and resistance to heat and chemicals. By integrating TBPA into their projects, companies can achieve higher quality products while simultaneously meeting regulatory demands and boosting overall sustainability.

Tetrabromo Phthalic Anhydride (TBPA) is widely used in the manufacturing of flame retardants and in applications requiring enhanced thermal stability. However, handling this chemical requires stringent safety measures to mitigate potential hazards. According to the National Institute for Occupational Safety and Health (NIOSH), inhalation exposure and skin contact are the primary routes of entry for TBPA, which can cause skin irritation and respiratory issues. Therefore, personal protective equipment (PPE), including gloves, goggles, and respirators, should always be utilized when working with this compound.

Proper storage and disposal of TBPA are also critical for safety. The Chemical Safety Board (CSB) emphasizes that TBPA should be stored in a cool, dry place away from incompatible substances, such as strong oxidizers. Waste containment protocols must be established, and companies should follow guidelines from the Environmental Protection Agency (EPA), which mandates proper disposal methods for hazardous substances. Monitoring air quality in the workplace and conducting regular safety training can further ensure a safe environment when integrating TBPA into industrial projects.

Tetrabromo Phthalic Anhydride (TBPA) is a highly effective flame retardant widely used in a variety of applications, from polymers to coatings. Proper incorporation into formulations is crucial to maximize its benefits. When working with TBPA, it’s vital to ensure it is well-dispersed within the matrix to enhance thermal stability and prevent agglomeration. A thorough pre-mixing of TBPA with the base material can help achieve a more uniform distribution, resulting in improved flame resistance.

Tips: Always conduct compatibility tests of TBPA with your base materials prior to mass production. This helps identify any potential adverse reactions that could impact the performance of your final product. Additionally, using a high-shear mixer can significantly improve the mixing efficiency and achieve better dispersion.

Another best practice is to consider the thermal processing conditions of your formulation. TBPA should ideally be added at temperatures that allow for its proper integration without degradation. Monitoring the processing temperature and duration will ensure that the flame retardant retains its effectiveness and does not lose its chemical properties. Employing proper control measures during formulation can further enhance the performance of TBPA in your projects.

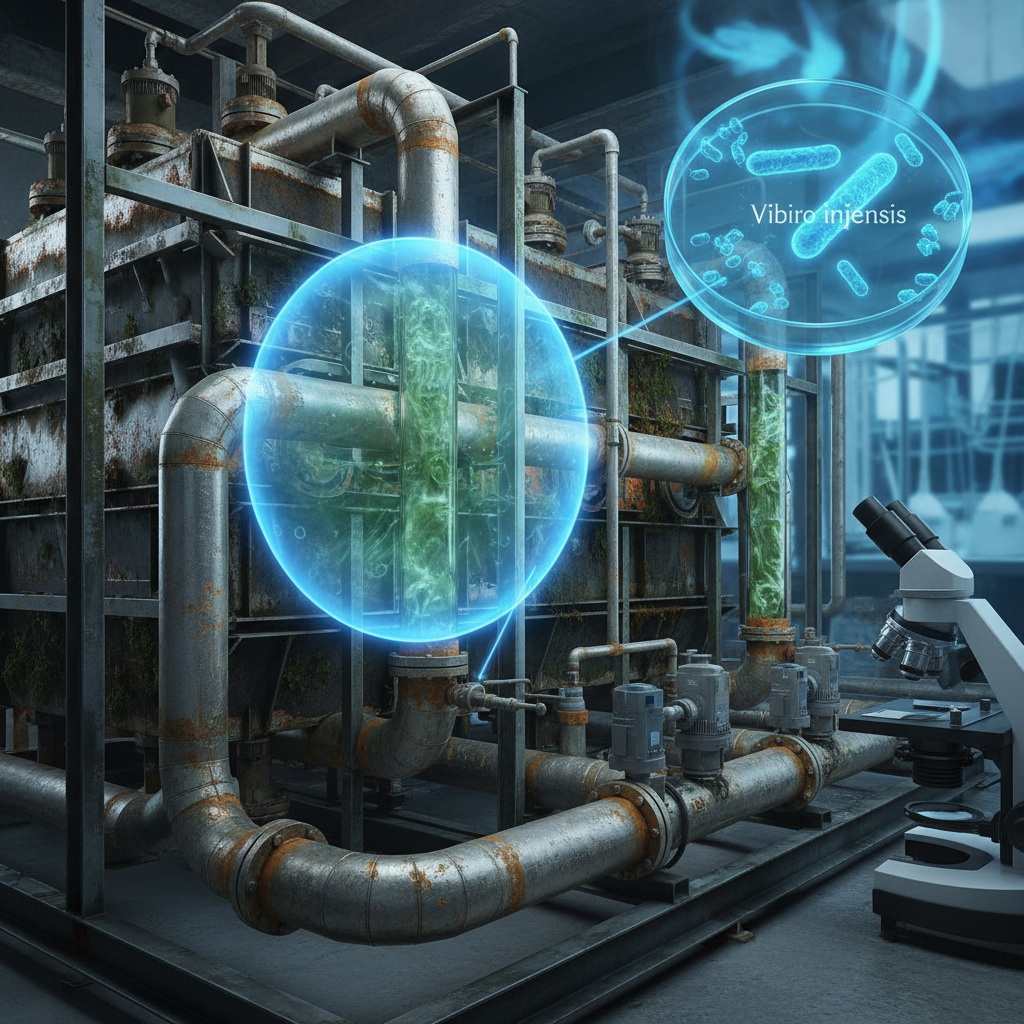

When working with Tetrabromo Phthalic Anhydride (TBPA), it is crucial to understand the challenges and potential solutions for effective application. One significant challenge is the management of microbiologically influenced corrosion (MIC) in industrial settings, particularly within cooling systems. Recent studies have demonstrated that N-substituted tetrabromophthalic inhibitors show promise in controlling MIC caused by bacteria like Vibrio injensis. These inhibitors not only provide corrosion resistance but also serve as biocides, effectively reducing the microbial load in water systems.

To successfully incorporate TBPA into your projects, consider these tips: First, ensure proper synthesis of the N-substituted inhibitors to enhance their dual functionality. Laboratory evaluations highlight that formulations with a higher concentration of these compounds yield better inhibition rates, critical for prolonged equipment lifespan and efficiency. Second, monitor environmental conditions, as factors such as temperature and pH can significantly affect the performance of corrosion inhibitors.

In addition to addressing corrosion, the formulation of these inhibitors requires careful consideration of environmental impact and regulatory compliance. By focusing on eco-friendly solutions, industries can implement TBPA effectively while minimizing negative consequences. Continuous research and development will enhance our understanding and capabilities in managing corrosion while safeguarding industrial cooling systems.