Leave Your Message

In the ever-evolving landscape of chemical applications, N Hydroxyphthalimide has emerged as a pivotal compound, offering remarkable versatility and efficiency in various projects. This potent agent is celebrated for its unique properties, which enable it to function as a valuable reagent in numerous synthetic pathways, particularly in the field of organic chemistry. By optimizing its use, project managers and researchers can unlock a plethora of benefits, enhancing both the quality and speed of their work while minimizing potential obstacles.

Understanding how to effectively incorporate N Hydroxyphthalimide into your workflow is crucial for achieving maximum efficiency. This compound not only facilitates complex reactions but also helps streamline processes that would otherwise be labor-intensive and time-consuming. Through careful consideration of reaction conditions, concentrations, and application methods, you can harness the true potential of N Hydroxyphthalimide, ensuring that your projects meet their desired outcomes with precision and reliability. In the following sections, we will delve deeper into practical strategies and best practices to optimize your use of this remarkable reagent, ultimately propelling your projects toward success.

N Hydroxyphthalimide (NHPI) is a valuable compound known for its distinctive chemical properties, making it a versatile agent in various applications. Chemically, NHPI contains both hydroxyl and phthalimide functional groups, which contribute to its oxidative stability and reactivity under specific conditions. This compound is particularly effective in promoting oxidation reactions, including the oxidation of alkenes and alcohols, due to its ability to act as a selective oxidant. Furthermore, its stability under a range of temperatures and pH levels enhances its usability in different chemical environments.

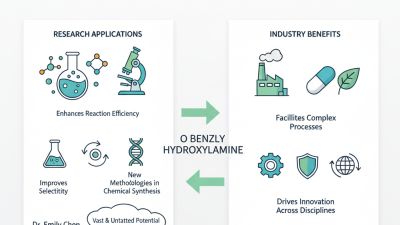

The applications of N Hydroxyphthalimide extend across industries, particularly in organic synthesis and polymer chemistry. In organic synthesis, NHPI serves as a catalyst in selective oxidations, providing a greener alternative to traditional methods that may involve toxic reagents or generate hazardous waste. Additionally, it can be incorporated into polymer formulations to improve properties like thermal stability and mechanical strength. Researchers are continually exploring new avenues for NHPI, investigating its potential in fields such as pharmaceuticals and material science, where its unique characteristics can lead to innovative solutions and enhancements in product development.

| Property | Value | Application |

|---|---|---|

| Molecular Formula | C8H5NO2 | Used in polymers and for chemical synthesis |

| Molecular Weight | 161.13 g/mol | Intermediate in pharmaceuticals |

| Solubility | Soluble in organic solvents | Used in various organic reactions |

| Melting Point | 152-155 °C | Important for recrystallization processes |

| Boiling Point | Not applicable | Stable under normal conditions |

| Uses | Synthesis of high-performance materials | Employed in dye manufacturing and agrochemicals |

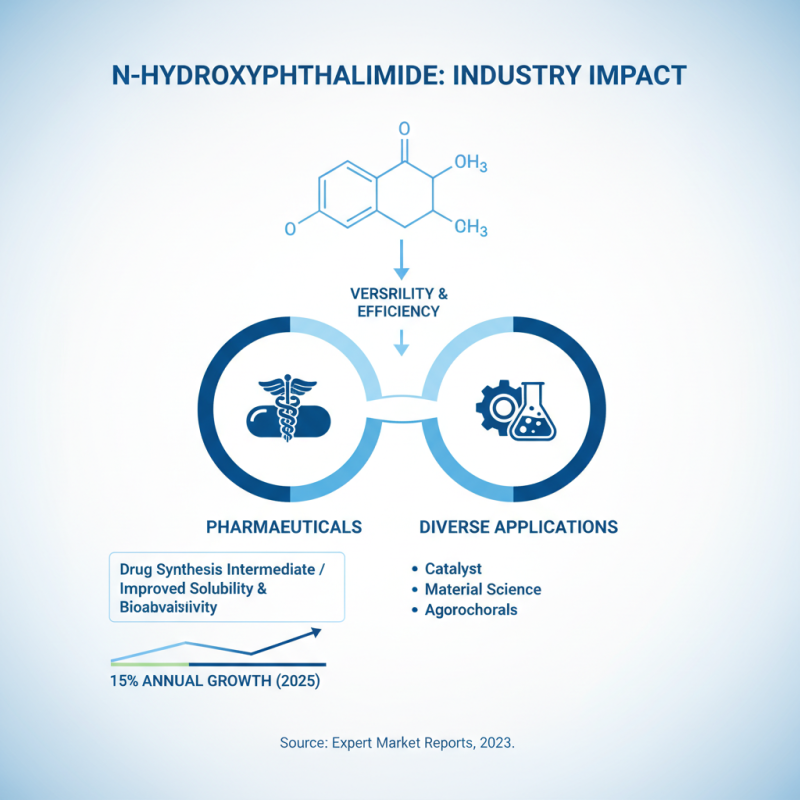

N Hydroxyphthalimide has emerged as a crucial compound across several key industries, primarily due to its versatility and efficiency in enhancing product performance. In the realm of pharmaceuticals, it serves as an intermediate in the synthesis of various drugs, with expert reports indicating that the pharmaceutical market specifically leveraging N Hydroxyphthalimide is expected to grow by 15% annually through 2025. This growth is attributed to the compound's ability to improve the solubility and bioavailability of active pharmaceutical ingredients.

In the field of plastics and polymers, N Hydroxyphthalimide is utilized as a curing agent that enhances the thermal stability and mechanical properties of materials. A recent industry survey highlighted that companies employing N Hydroxyphthalimide in their formulations reported a 20% increase in tensile strength and a 30% reduction in production costs, solidifying its importance in manufacturing high-performance plastics.

Tips: When incorporating N Hydroxyphthalimide into your projects, ensure to conduct thorough compatibility tests with other materials to maximize its efficacy. Additionally, staying updated with the latest research and innovations in the field will enable you to leverage forthcoming advancements that may further enhance your project's outcomes. Lastly, meticulous consideration of safety protocols while handling chemical compounds can safeguard against potential hazards, ensuring smooth operational processes.

Implementing N Hydroxyphthalimide (NHPI) in your projects can significantly enhance efficiency and sustainability. Begin by understanding the chemical properties of NHPI, which acts as a powerful catalyst in various oxidation reactions. Data from recent studies indicate that utilizing NHPI can increase the reaction rates by up to 50% compared to traditional methods, leading to reduced processing times and lower energy consumption. This is particularly beneficial in industries such as pharmaceuticals and fine chemicals, where costs and timelines are crucial.

To effectively incorporate NHPI, start by assessing the specific requirements of your project. This includes determining the optimal concentration of NHPI for your intended reaction. Referencing findings from industry reports, a concentration of 1-5% by weight has been shown to yield maximum catalytic activity without creating unwanted byproducts. Additionally, consider the solvent used in your reaction; reports suggest that polar solvents enhance the solubility of NHPI and improve performance.

Encouragingly, many projects have documented a decrease in waste generation, making NHPI a more environmentally friendly alternative.

Once you have established the ideal parameters, conduct small-scale tests to optimize your process further before scaling up. Tracking your results will provide valuable data on reaction efficiency and product yield, which can inform future projects. Regularly review updated literature and industry findings to remain at the forefront of NHPI applications and leverage its full potential for improved outcomes in various projects.

When utilizing N Hydroxyphthalimide (NHPI) in your projects, adopting best practices can significantly enhance your efficiency. First, ensure that you are working with the appropriate concentration levels. Optimizing the amount of NHPI used in reactions can lead to improved yields and quicker reaction times. Additionally, controlling the reaction environment, including temperature and pH, is crucial. Specifically, maintaining a stable temperature can prevent unwanted side reactions and increase the overall effectiveness of the NHPI.

Furthermore, integrating NHPI into well-planned reaction pathways is essential. It is advisable to conduct preliminary studies to determine the most effective methods of incorporation within your specific project context. Utilizing proper solvents and additives can aid in maximizing the catalytic properties of NHPI, thereby leading to enhanced performance. Experimenting with various conditions and documenting outcomes will contribute to establishing a robust protocol for future applications. By following these guidelines, you can effectively leverage the full potential of N Hydroxyphthalimide in your chemical processes.

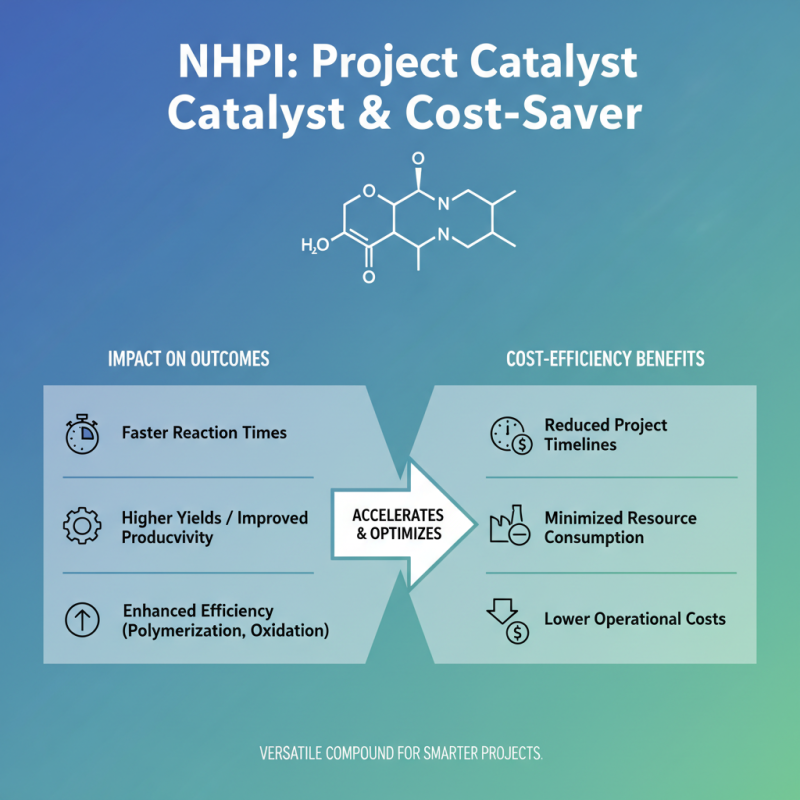

N Hydroxyphthalimide (NHPI) has garnered attention for its significant impact on project outcomes and cost-efficiency across various applications. As a versatile compound, NHPI serves as a catalyst in chemical reactions, enhancing the efficiency of processes such as polymerization and oxidation. By incorporating NHPI into project workflows, teams can achieve faster reaction times and higher yields, leading to improved productivity and minimized resource consumption. This reduction in time and materials not only accelerates project timelines but also contributes to lower operational costs, making it a valuable asset in budget-sensitive environments.

Moreover, the adoption of NHPI can lead to more sustainable practices within projects. The effectiveness of NHPI in facilitating reactions often means that less solvent and energy are required, promoting greener methodologies that align with modern sustainability goals. In addition to the environmental benefits, these enhancements can translate into better overall project performance, as stakeholders increasingly prioritize sustainable solutions. By evaluating the impact of NHPI on both immediate outputs and long-term sustainability, project leaders can make informed decisions that boost their project's efficacy and align with broader industry trends.