Leave Your Message

O Phthalic Anhydride, a pivotal chemical in the production of various products, plays an essential role in modern industry. As emphasized by Dr. Emily Zhang, a leading expert in polymer chemistry, “Understanding the nuances of O Phthalic Anhydride is crucial for optimizing its applications in the manufacturing sector.” This statement underscores the importance of comprehensively understanding the properties, uses, and production of O Phthalic Anhydride, as well as the safety considerations surrounding its use.

In this article, we will delve into the multifaceted world of O Phthalic Anhydride, exploring its diverse applications ranging from the production of plastics and resins to its significance in the automotive and electronics industries. Additionally, we will discuss the various methods of producing this vital chemical, highlighting innovative approaches and advancements that have emerged in recent years. Lastly, safety tips will be provided to ensure that individuals handling O Phthalic Anhydride are well-informed of the precautions needed to mitigate potential risks associated with its use. Through this exploration, we aim to equip readers with a thorough understanding of O Phthalic Anhydride, setting the stage for safe and effective application in various industrial contexts.

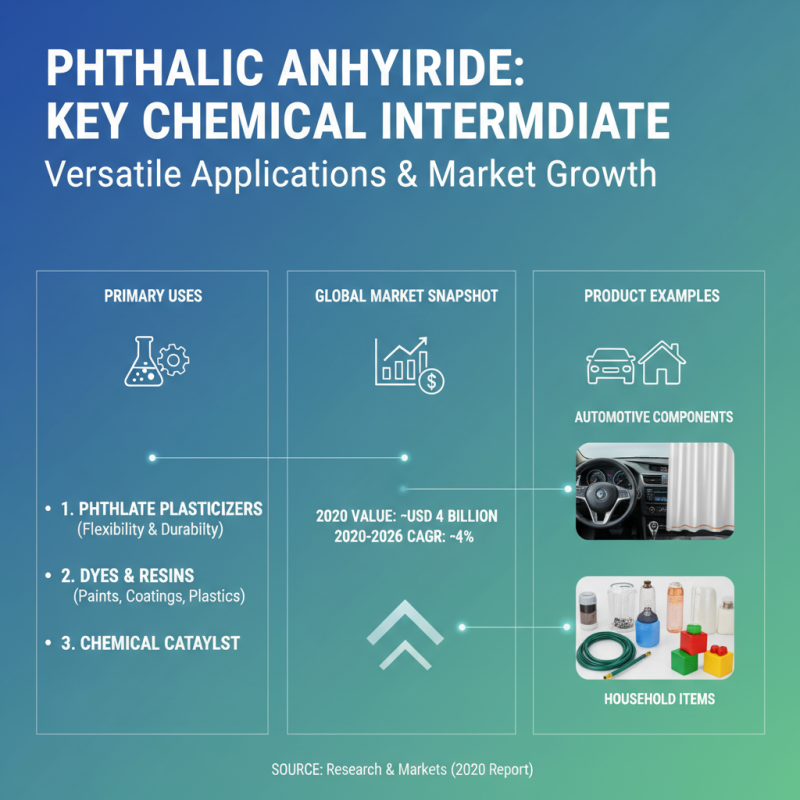

O Phthalic Anhydride, a key chemical intermediate, is primarily utilized in the production of phthalate plasticizers, as well as in dyes, resins, and as a catalyst in various chemical reactions. According to a report by Research and Markets, the global phthalic anhydride market was valued at approximately USD 4 billion in 2020, with expectations to grow at a compound annual growth rate (CAGR) of around 4% through 2026. The widespread applications of O Phthalic Anhydride highlight its importance in enhancing the flexibility and durability of products ranging from automotive components to household items.

Production of O Phthalic Anhydride typically involves the oxidation of ortho-xylene or naphthalene, predominantly through the process known as "catalytic oxidation." This process has been refined over the years to improve yield and reduce environmental impact, reflecting a growing trend towards sustainable practices in the chemical industry. Data from the International Chemical Industry Association indicates that innovative production techniques could decrease emissions by over 30%, aligning with global sustainability targets.

Safety measures are crucial when handling O Phthalic Anhydride, given its irritant properties and potential health risks. The Chemical Safety Data Sheet (CSDS) highlights the necessity of using appropriate personal protective equipment (PPE) to mitigate exposure. Furthermore, it emphasizes the importance of proper storage and handling protocols to minimize the risk of accidents and ensure safe operational practices in industrial settings.

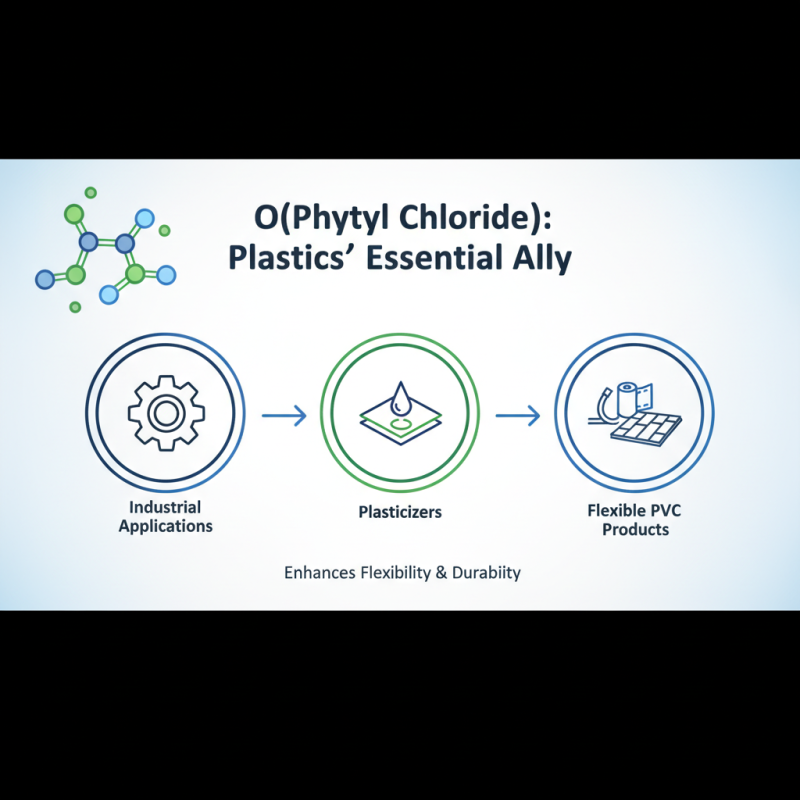

O Phthalic Anhydride is a versatile chemical compound widely used in various industrial applications. One of its primary uses is in the production of plasticizers, which are crucial for enhancing the flexibility and durability of plastic materials. These plasticizers are commonly incorporated into products such as polyvinyl chloride (PVC), making them essential in the manufacturing of flexible films, cables, and flooring materials. The ability of O Phthalic Anhydride to provide vital performance characteristics makes it an indispensable component in the plastics industry.

In addition to its role in plastic manufacturing, O Phthalic Anhydride is also utilized in the synthesis of dyes and pigments. This compound serves as a key ingredient in the formulation of various colorants, which are essential in industries ranging from textiles to coatings. Its chemical properties allow it to produce vibrant and stable colors, thereby enhancing the aesthetic appeal of consumer products. Furthermore, it is used in the production of resins and alkyd paints, contributing to the overall improvement of product performance and longevity. The diverse applications of O Phthalic Anhydride highlight its importance across multiple sectors, making it a valuable commodity in the chemical industry.

O Phthalic Anhydride, a key chemical in industry, is commonly produced through various methods that cater to different production scales and environmental considerations. The most widely used method is the oxidation of naphthalene or orthoxylene, often occurring in the presence of a catalyst. In these processes, the hydrocarbons undergo oxidation at high temperatures, resulting in O Phthalic Anhydride. Additionally, some manufacturers employ a more modern approach using catalytic oxidation, which enhances efficiency and reduces the carbon footprint.

When engaging in the production of O Phthalic Anhydride, safety is paramount. Always ensure that proper PPE (personal protective equipment) is used, including gloves, goggles, and masks, to protect against any chemical exposure. Adequate ventilation in the workspace is crucial to mitigate inhalation risks during production processes. Furthermore, regular training sessions should be conducted for all personnel involved in handling this substance to reinforce safe practices and emergency response strategies.

Another tip for ensuring optimal production is to monitor the reaction parameters closely. Maintaining the correct temperature and pressure during the oxidation processes can significantly influence the yield and quality of O Phthalic Anhydride. Utilizing advanced monitoring technologies can help maintain these critical conditions, ensuring both efficiency and safety in production. By adhering to these tips, producers can enhance their operational effectiveness while safeguarding their workforce and the environment.

| Aspect | Details |

|---|---|

| Chemical Formula | C8H4O3 |

| Uses | Production of plasticizers, dyes, resins, and certain pharmaceuticals |

| Production Methods | 1. Oxidation of ortho-xylene 2. Phthalic acid dehydration |

| Safety Tips | Use appropriate PPE, work in a well-ventilated area, avoid skin and eye contact |

| Environmental Impact | Can contribute to air pollution; proper disposal is necessary |

| Storage Recommendations | Keep in a cool, dry place away from direct sunlight |

| Physical State | Solid, white crystalline substance |

When handling O Phthalic Anhydride, adherence to safety protocols is crucial due to its potential health hazards. Primarily used in the production of polyesters and resins, this chemical can cause irritation to the skin, eyes, and respiratory tract upon exposure. According to the United Nations Globally Harmonized System (GHS), O Phthalic Anhydride is classified as a hazardous substance, necessitating the implementation of strict safety measures. Personal protective equipment (PPE) including gloves, safety goggles, and respiratory protection should be worn to minimize risk. Moreover, ensuring adequate ventilation in the workspace is essential to prevent accumulation of vapors.

Proper storage and handling procedures also play a critical role in ensuring safety while working with O Phthalic Anhydride. It is advised to store this chemical in a cool, dry place, away from incompatibles like strong acids and bases. Safety data sheets (SDS) should always be readily available, providing information on handling, spill response, and first aid measures. The National Institute for Occupational Safety and Health (NIOSH) recommends monitoring workplace exposure levels to maintain air quality within permissible limits, as elevated concentrations can lead to acute health issues. By prioritizing safety and implementing comprehensive handling guidelines, risks associated with O Phthalic Anhydride can be effectively managed, ensuring a safer working environment.

This bar chart illustrates the various dimensions related to O Phthalic Anhydride, including its primary uses as a chemical intermediary, the estimated production volume, and the reported safety incidents. The data represents general insights into its application and safety management in industrial contexts.

O Phthalic Anhydride (OPA) is a chemical compound widely used in the production of plastics, resins, and dyes. However, its use raises significant environmental concerns. The production process of OPA can lead to the release of harmful byproducts and volatile organic compounds that can affect air and water quality. Consequently, numerous regulations have been established to mitigate these environmental impacts, demanding stringent monitoring of emissions during manufacturing and proper waste management practices.

To comply with environmental regulations, industries utilizing OPA must adopt best practices in pollution control. This includes implementing technologies for capturing emissions, reducing waste, and ensuring safe handling and storage of the chemical. Regulatory bodies often require regular assessments and reports on environmental impact, driving companies to invest in more environmentally friendly practices. Moreover, ongoing research into alternative compounds that can replace OPA in various applications is essential to minimize ecological risks and promote sustainability in the chemical industry.