Leave Your Message

Phthalic Anhydride is a vital chemical in manufacturing. It serves numerous applications in various industries, such as plastics and coatings. With its unique properties, Phthalic Anhydride contributes to producing high-performance materials.

In chemical manufacturing, understanding Phthalic Anhydride's role is crucial. It's widely used in creating plasticizers, resins, and pigments. These products enhance the quality and durability of materials. However, knowledge about handling and safety is often insufficient.

Some processes require careful management. Misuse or poor handling of Phthalic Anhydride can lead to environmental challenges. Manufacturers must reflect on safety protocols. Continuous training for workers is necessary. Through proper use, industries can maximize the benefits while minimizing risks. Each step matters in this complex chemistry landscape.

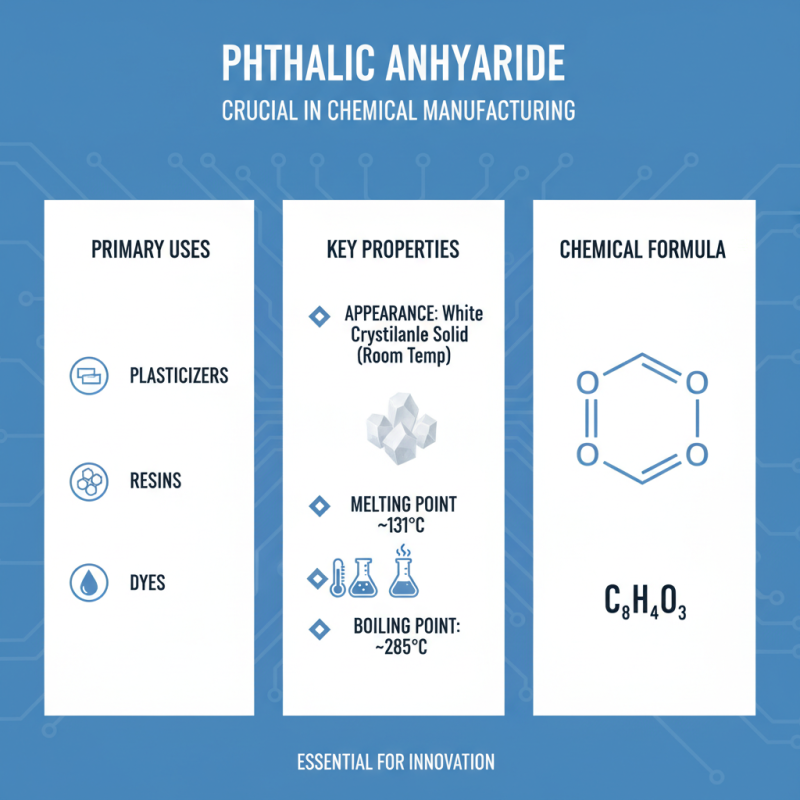

Phthalic anhydride is a crucial compound in chemical manufacturing. It is mainly used to produce plasticizers, resins, and dyes. Understanding its chemical properties is vital for effective application. The compound is a white crystalline solid at room temperature. It melts at about 131 degrees Celsius and boils around 285 degrees Celsius.

When it comes to its reactivity, phthalic anhydride can undergo hydrolysis, yielding phthalic acid. This reaction is significant for various applications. Additionally, it can react with alcohols to form esters. These esters are useful in plastics and coatings. However, controlling the reaction conditions can be challenging. Sometimes, impurities affect the final product.

One must also consider the potential environmental impacts during production. While phthalic anhydride itself is not hazardous, its manufacture can generate waste. The process requires careful planning and management of resources. Thus, one should reflect on optimizing processes to minimize waste. Such considerations are crucial for sustainable chemical manufacturing practices.

Phthalic anhydride plays a crucial role in the chemical manufacturing industry. Its versatility enables various applications. One major use is in the production of plasticizers, which help improve the flexibility of plastics. The global plasticizers market was valued at approximately $20 billion in 2022, with phthalic anhydride-derived plasticizers holding a significant share.

Another key application is in the synthesis of resins. Phthalic anhydride is essential in producing alkyd resins, used in paints and coatings. The demand for eco-friendly coatings is pushing the market for these resins. According to industry reports, this segment is expected to grow at a CAGR of 5.1% from 2023 to 2030. However, companies must consider the environmental impact of phthalic anhydride. Increasing regulation may challenge future growth in this area.

In the field of agriculture, phthalic anhydride is used in the production of agricultural chemicals. This sector is becoming more competitive, necessitating innovation. Producers should explore alternative methods that minimize waste and reduce environmental footprints. There is ongoing debate about balancing productivity with sustainability. Addressing these concerns is essential for the future of phthalic anhydride in chemical manufacturing.

Phthalic anhydride is vital in chemical manufacturing. Its synthesis is straightforward, yet requires precision. The two main methods for producing phthalic anhydride are the oxidation of naphthalene and the oxidation of o-xylene. Each method has unique advantages and challenges.

The oxidation of naphthalene is efficient. It involves high temperatures and specific catalysts. This method offers high yields, typically around 90%. However, it can produce side products, complicating purification. On the other hand, o-xylene oxidation is more controlled and can be done under milder conditions. Yet, it often yields less phthalic anhydride compared to naphthalene.

In an industry report by Grand View Research, the global phthalic anhydride market was valued at approximately $4.3 billion in 2022. This highlights its importance in the market. As manufacturing processes evolve, the demand for phthalic anhydride will likely increase, aiming for greener methods. However, careful monitoring of environmental impacts is necessary. Balancing production efficiency and sustainability is a challenge that needs constant reflection.

Phthalic anhydride is widely used in chemical manufacturing. However, it poses specific safety challenges. Proper handling is crucial to prevent health risks. Exposure can lead to respiratory issues, skin irritation, or eye damage. The American Conference of Governmental and Industrial Hygienists (ACGIH) recommends an exposure limit of 0.1 mg/m³ for anhydride vapors. This limit protects workers from potential adverse effects.

When working with phthalic anhydride, personal protective equipment (PPE) is essential. Respirators, gloves, and goggles should always be worn. Ensure good ventilation in work areas to reduce inhalation risks. Data from the National Institute for Occupational Safety and Health (NIOSH) indicates that mishandling can lead to accidents. Inadequate training and lack of awareness are often the primary reasons for incidents.

Companies should foster a culture of safety. Regular training can enhance awareness and adherence to safety protocols. Incorporating material safety data sheets (MSDS) into employee onboarding is essential. Misunderstanding safety guidelines can have dire consequences. Every facility's approach to handling should also include regular audits and assessments. Reflecting on past incidents can guide better practices in the future.

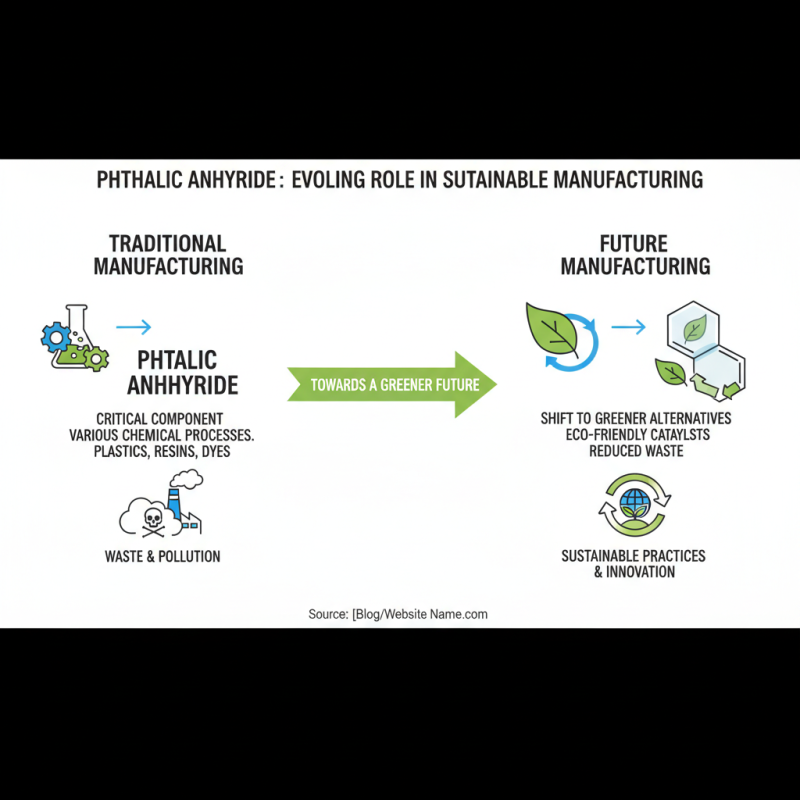

Phthalic anhydride has long been a critical component in various chemical processes. In the coming years, its role in manufacturing may evolve significantly. Industries are increasingly focused on sustainable practices. The use of phthalic anhydride could shift towards greener alternatives. Companies might explore eco-friendly catalysts or processes that reduce waste.

Moreover, innovation in product formulation could lead to improved applications. For instance, more efficient production methods might emerge. These innovations may not yet be widely adopted but present an opportunity for growth. Companies must remain vigilant. They need to address the environmental impact of phthalic anhydride use.

As regulations tighten, businesses face challenges in compliance. The future will demand a balance between utility and sustainability. Experimentation with new technologies is essential but risky. Stakeholders must consider potential pitfalls and invest in responsible practices. The evolving landscape of phthalic anhydride usage invites both reflection and action.