Leave Your Message

Tetrabromo Phthalic Anhydride (TBPA) is gaining importance in various industrial applications. This compound is widely used in flame retardants, coatings, and plastics. The global market for TBPA has witnessed substantial growth, increasing by nearly 15% annually over the past five years, according to industry reports from Global Market Insights.

In manufacturing, TBPA serves as an effective additive, enhancing the fire resistance of materials. It is particularly valuable in the electrical and electronics sectors, where safety is paramount. However, challenges remain. The production process can be costly and require stringent safety measures. Additionally, users must consider the environmental impact of TBPA. Recent studies indicate the need for thorough assessments to balance performance with sustainability.

Adopting TBPA into production requires careful evaluation. The industry's growth prospects are promising, but potential hazards should not be overlooked. Companies must reflect on their practices to ensure safe and responsible use. Emphasizing the importance of research and innovation will help overcome these barriers. Being aware of these factors is crucial for the optimal utilization of Tetrabromo Phthalic Anhydride in industrial settings.

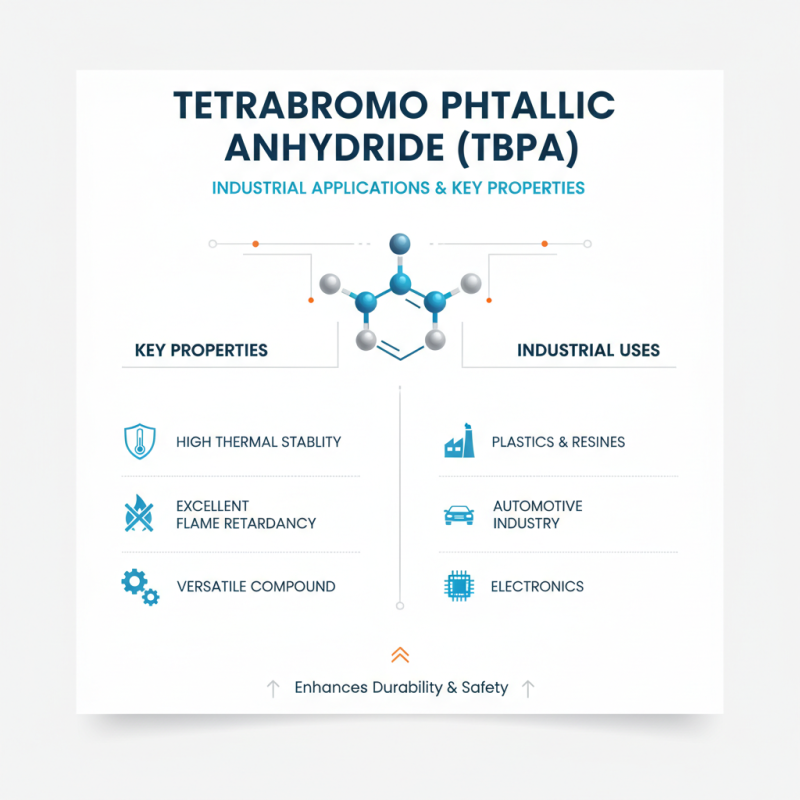

Tetrabromo Phthalic Anhydride (TBPA) is a significant compound in industrial applications. Its unique properties make it valuable in various sectors. TBPA boasts high thermal stability and excellent flame retardancy. This makes it ideal for use in resins and plastics, particularly in the automotive industry.

In coatings, TBPA enhances fire-resistance. It provides a protective barrier, thus, extending the life of products. However, handling TBPA requires caution. Proper safety protocols must be in place. Use gloves and masks to avoid inhalation or skin contact.

Tips: Always store TBPA in a cool, ventilated area. This prevents degradation and maintains potency. Consider environmental impacts when using TBPA. It's crucial to follow local regulations for disposal. Mismanagement can lead to unintended consequences, particularly in safety and health. Being mindful reduces risks.

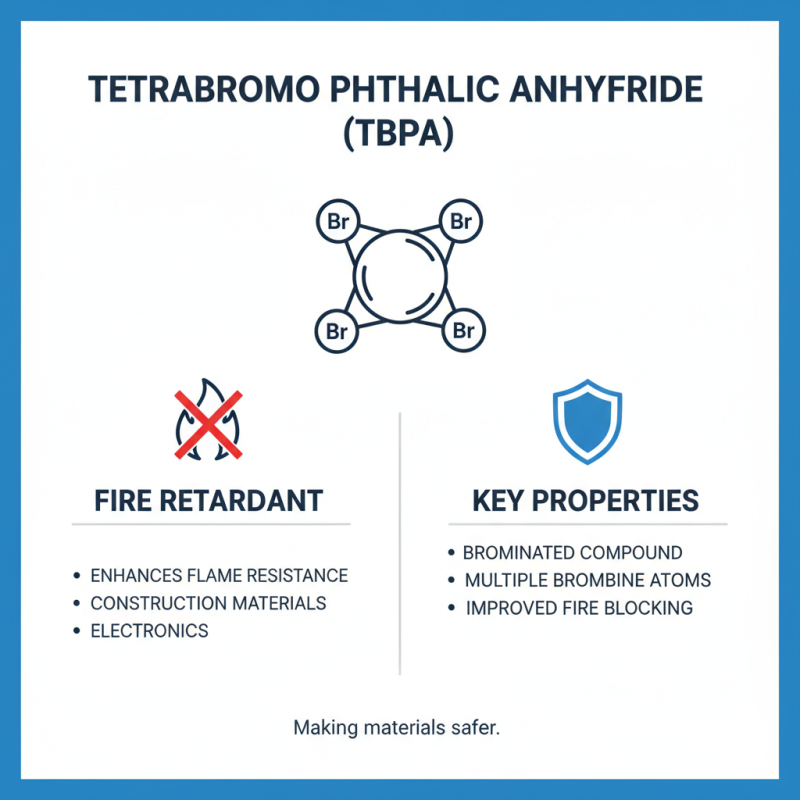

Tetrabromo Phthalic Anhydride (TBPA) is often used in fire retardants. It effectively enhances the flame resistance of various materials, especially in construction and electronics. TBPA is a brominated compound, which means it has multiple bromine atoms that provide better flame retardant properties.

When using TBPA, it's crucial to consider its compatibility with other materials. Not all substrates respond well to TBPA. For best results, conduct preliminary tests. This ensures that the final product meets safety and performance standards.

Tips: Always handle TBPA with care. Proper ventilation is necessary during application. Also, keep safety gear on hand. Evaluate the whole system for fire risks.

Fire safety regulations can vary, impacting the use of TBPA. Local guidelines should direct your manufacturing processes. Remember, while TBPA can improve fire resistance, over-reliance may mask other safety issues. It’s essential to evaluate the entire fire prevention strategy, not just individual components.

Tetrabromo phthalic anhydride (TBPA) (TBPA) holds significant value in the coatings and plastics industries. Its flame-retardant properties make it an essential component. Many manufacturers incorporate TBPA into formulations to enhance safety and reduce fire hazards. This application is crucial, especially in products aimed at electronics and construction.

In coatings, TBPA aids in improving performance. It offers durability and resistance to environmental factors. However, the balance between flame retardance and other properties can be tricky. Some formulations may end up less effective than intended. The challenge lies in achieving the right mix. It's not always straightforward.

Plastics benefit from TBPA's properties as well. It enhances thermal stability, making products more reliable. Yet, there are cases where the use of TBPA leads to issues in processing. Manufacturers must carefully assess how TBPA interacts with other materials. Observing these interactions is vital for optimal performance. Continuous evaluation is necessary to ensure both safety and efficacy in the final products.

Tetrabromo phthalic anhydride (TBPA) is gaining traction in polymer blends. Its flame-retardant properties make it critical for safety in many applications. According to recent industry reports, TBPA can reduce flammability by up to 30% in various plastic materials. This reduction in fire risk is particularly vital for electronics and automotive components.

Optimizing TBPA in blends is a nuanced process. The ideal concentration often lies between 5% and 15%. Too little may not sufficiently enhance fire safety, while excessive amounts can compromise mechanical properties. This delicate balance requires thorough experimentation and adjustment. While some manufacturers have reported success with TBPA, others note issues such as brittleness in certain blends. Adapting to different polymers is essential.

In real-world applications, the use of TBPA can pose challenges. Plastics containing TBPA often require careful processing conditions. Otherwise, the material can degrade. This degradation may lead to lower performance in end products. Despite its benefits, the long-term effects of TBPA in polymer blends remain an area for further investigation. Users must monitor how TBPA interacts with other additives to avoid unforeseen issues.

The market for Tetrabromo Phthalic Anhydride (TBPA) is on the rise. Recent studies indicate a growing demand in industrial applications such as flame retardants and materials synthesis. By 2026, the global market for TBPA is expected to expand significantly, driven by various sectors including automotive, electronics, and construction. A report by MarketsandMarkets forecasts a CAGR of 5% from 2023 to 2026.

Industry professionals should remain aware of shifting market dynamics. There may be challenges in sourcing TBPA due to regulatory changes or supply chain disruptions. This can affect production timelines. Therefore, companies should build flexibility into their purchasing strategies.

Tip: Regularly monitor market reports. They can reveal trends and potential shifts in consumer behavior.

Additionally, environmental concerns are shaping how industries approach TBPA. Some manufacturers are exploring greener alternatives. This could impact demand and affect pricing. Companies should evaluate their product lines and consider sustainability.

Tip: Engage in dialogues with suppliers about eco-friendly innovations in TBPA production. Building these relationships can be advantageous in adapting to market changes.